Reliable Coal Pulverizers and Mills » Babcock & Wilcox

What Is A Coal Pulverizer? Pulverization is currently the most preferred method for preparing coal for burning. Coal Pulverizers help to mechanically smash and grind coal into a fine powder, enabling it to be burnt like gas. This increases the efficiency of combustion.

Coal Pulverizer at Rs 225000/piece Coal Pulverizer in Ahmedabad ID

Holmes Coal Pulverizers are bench-type units that perform well in reducing coal or coke from No. 4 to No. 60 sieve size. Models are available with manual or auger feed.. Five screen plates are supplied with each machine. Select from six available screen opening sizes No. 80, No. 60, No. 40, No. 30, No. 20, and No. 10 (0.180, 0.250, 0.425, 0..

Mild Steel Laboratory Coal Pulverizer Machine Manufacturer, For

pulverizer is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal combustion in the steam-generating furnaces of coal power plants. Types of coal pulverizersedit. Coal pulverizers may be classified by speed, as follows: [1] Medium Speed. High Speed.

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Are you looking for a direct-fired coal pulverizer, a low-capacity coal size reduction machine, or something in between? Williams has you covered. At Williams Patent Crusher, we set ourselves apart from other crusher and pulverizer companies. This is done with our diverse product line and customized systems for a variety of applications.

Coal Pulverizer at Rs 1.50 Lakh / unit in Ahmedabad Fabtech Engineers

Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion. Pulverizers have three functions, pulverization, drying and classification. The classification function plays the important role of ensuring that only fine particles of the pulverized coal.

Coal Pulverizer at Best Price in India

Coal feeders Pulverizers (grinding mills and crushers) Screens (vibrating screens or trommel screens) Spiral classifiers Floatation machines Mixers Dryers More on these down in the guide: The 5-step process to pulverize coal efficiently The coal pulverization process involves a precise sequence of steps.

Coal PulverizerDongding Drying Equipment

Diverse coal pulverizer machines are accessible in the market, performing different functions. The four main classifications include ball tube mills, impact mills, vertical roller mills, and Ring-Roll and Ball-Race. Each of these utilizes a four-step process to ensure proper pulverization, including drying, grinding, classification, and.

Coal Pulverizer Machine at best price in New Delhi by Chi Care Global

How A Coal Pulverizer Works - Coal Grinding Process | 3D Animation | Williams Patent Crusher - YouTube © 2023 Google LLC Here's a 3D animation of how a coal grinding system works. Williams.

Coal Pulverizer Machine DONGDING DRYER

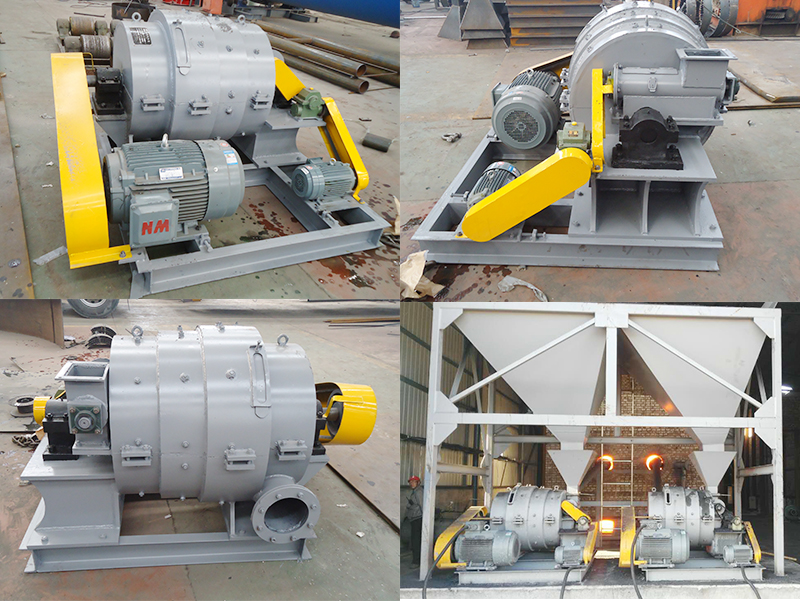

In the first computational example the coal pulverizer drive system is considered. This machine is driven by the 22 kW asynchronous motor by means of the reduction planetary gear of the resultant ratio 1:5.33.

Coal Pulverizer & Injection Machine JXSC Machine

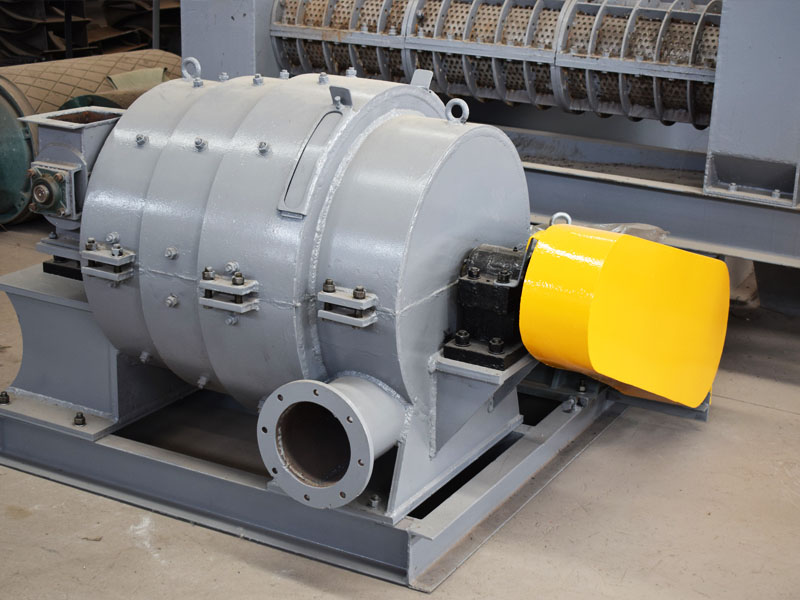

The coal pulverizer and injection machine is a combined machine of hammer mill crushing and centrifugal air supply used for pulverizing coal and spraying coal powder directly into the combustion chamber for combustion in various reaction furnaces, boilers, drying kilns, tunnel kilns, annealing ( annealing) kiln, etc. 【MP Series Coal Pulverizer】 The MP series coal pulverizer is based on the.

Coal Pulverizers Machine at Rs 50000/piece Coal Pulverizer in Kanpur

As a premier industrial crushing equipment manufacturer, Stedman Machine Company provides consulting services, custom designs, project planning, and more. Contact us!. One of the first uses for the cage mill was as a coal pulverizer. By 1900 Nathan Stedman had built more than 100 cage mills designed to crush coal. Read More.

Mild Steel Three Phase Coal Pulverizer Machine, 5 Hp50 Hp at Rs 400000

The air-swept ball mill, also often referred to as coal mill or coal pulverizer, has the advantages of high production capacity and high coal flexibility, so it is favored by power plants. Table of Contents How does a Coal Pulverizer work? What Are Coal Pulverizer Parts? How To Maintain A Coal Mill? Common Faults Of Coal Pulverizer

Coal Pulveriser Machine Manufacturers India, Industrial Pulveriser

A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal several centimeters in diameter down to fine particles. The pulverizer includes pulverization, drying and classification functions. The classification function plays the important role of ensuring that only fine particles are sent to the boiler.

China Coal Grinding Mill/Coal Mill Pulverizer/Coal Pulverizing Machine

Applications Energy & Biomass Energy & Biomass Pulverizers Designed in 1886 by Nathan Stedman, one of the first applications of the cage mill to process materials for the energy industry. Today, Stedman has evolved and remains a leading energy pulverizer manufacturer. Contact Us Biomass Grinding Machine H-Series Impact Mill

3 Phase Shubh Coal Pulverizer, Micro Pulverizer Manufacturing Works

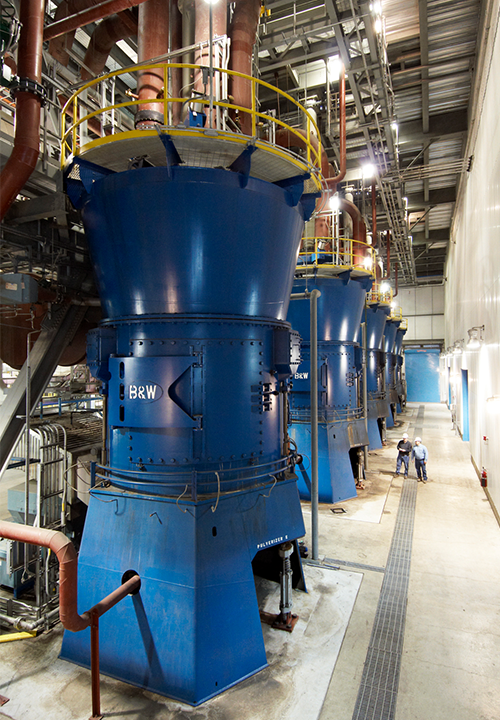

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Mild Steel Coal Fired Pulverizer Machine, For Grinding, 3 Hp, Rs

The coal-pulverizer is an important unit, which pre-processes coal-fuel fed to the boiler in coal-based thermal power plants. It is extremely important to comprehend the operational behavior of the coal pulverizer unit for good performance of the boiler and overall coal power-plant. This paper describes the first principle based energy and mass.